CORPORATE

Investors

We believe that with EAWD, you have a unique opportunity to invest in:

Turnkey Technologies from Germany & Other European countries.

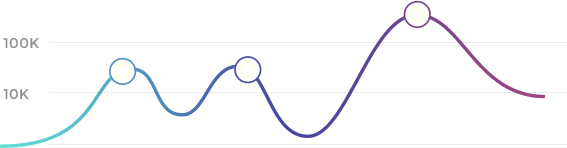

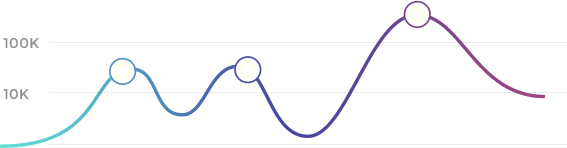

EAWD Chart by TradingView

In view of the ever-increasing worldwide demand for water and energy, EAWD endeavours to make available environmentally-friendly and sustainable methods of producing and purifying water, in addition to the generation of energy.

Powered by renewable energy

At EAWD we have the decentralized and independent energy solutions

Solar energy solutions

Performance over the long-term requires a high level of knowledge transfer to our customer

Solar Powered Atmosphere Water Generation

Water procurement through the use of ultra efficient refrigeration technology for condensation of the air.

• Totally independent from groundwater resource

• Provides unlimited water resourse

• No negative effects on the environment

• Avoids Transportation and Storage of water to a great extent as water is produced at the point and time of use and above all;

• It does not required energy from the grid

We believe that with EAWD, you have a unique opportunity to invest in:

Turnkey Technologies from Germany & Other European countries.

EAWD was created on the premise that there isn’t only one solution that addresses the problematic issue of water scarcity, nor the energy generation and/or saving needs of our World.

We assist our customers to find the best technical solution. If required, our team is involved from an early stage of the Project planning until final installation and running operation.

We provide engineering studies and analysis to ensure project sustainability, with a specialization in Water & Energy Technologies.

To cope with water scarcity, generate clean energy dealing with the actual waste problem, benefits without harming the planet.